APPEARANCE AND REALITY

A tour of European trade fairs and marinas reveals which marketing campaigns and promotions have gained the most traction and highlights the latest trends and developments to have been packaged up, badged (invariably) as important improvements and sold on to the sailing public. Most producers bringing new products to market aim to square the circle of performance, utility value and living space, which may well be OK for the ordinary sailor who has no real intention of venturing beyond the reach of the maritime emergency services. Boats that are going to visit the high seas, on the other hand, need to be judged against a quite different set of criteria in my opinion, criteria that seem to me as a rule to receive far too little attention when it comes to marketing and promotion. One such criterion is the design and robustness of the appendages.

WATCH OUT FOR THE CRUNCHY BITS …

Insurance company records on the frequency and causes of claims leave no doubt that rudder design and construction have become the Achilles’ heel of modern yachts. Part of the reason for this unfortunate state of affairs is that so many of the European yacht manufacturers buy in industrially manufactured rudders from external suppliers, presumably for cost reasons. Well-made as they are (see Jefa, for example), these rudders are by their nature installed with just two bearings – two bearings that can be really quite close together on some of the hull designs with which they are used. A skeg is often omitted, which simultaneously improves the effectiveness of the rudder and reduces costs.

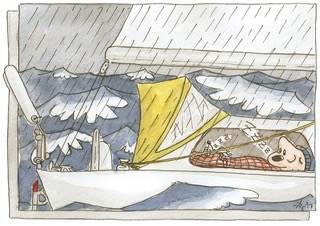

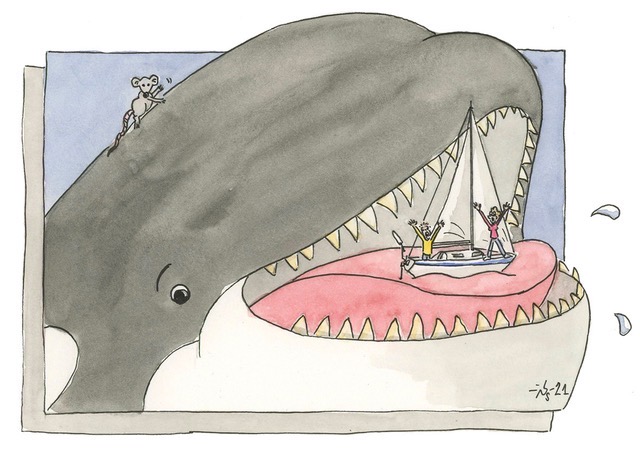

Anyone thinking of heading offshore with a boat sporting a rudder of this description may wish to consider investing in a guardian angel (complete with snow plough) to keep it clear of anything solid hanging around close to the surface. This is a matter that any sailor planning a big trip needs to start thinking about right at the beginning of the process (and certainly before buying a boat for the job), which makes it all the more remarkable that so little effort is made to raise awareness of the issues. I have a personal interest in this sort of thing, as it happens. I am always pleased to offers sailors my advice when asked, but the pleasure is that much greater if they ask me while there is still time for my words to make a difference. If the people concerned have already put their money into (what I consider to be) an unsuitable craft, I can but politely wish them good luck with their new purchase (and hope they have that guardian angel standing by).

ADVICE AND THE CONSEQUENCES – AND HOW THE US AND EUROPE DIFFER

The job of administering advice and recommendations in the US market lies in the hands of the countless bluewater sailors and sometime authors who record and publish their own experiences, very often gained aboard robust long keelers, through their own small publishing houses. The typical bluewater yacht in the US follows traditional lines, with the main rudder hung on the back of the keel or a substantial skeg. Long-distance cruisers in the US seem to have little love for modern performance yachts.

The situation in Europe is very different. On this side of the Atlantic we are quite used to seeing in print so-called test reports that clearly amount to little more than advertorials. These puff-piece slices of favourable press cobbled together in exchange for a full-page advert or two are prone to praising much while scrutinizing very little – and construction and practicality at sea are two of the crucial issues often overlooked. These reports are continuously referenced by manufacturer and publisher alike and can even be found years later being offered for sale as a download. There exists a clear and present danger, in other words, that the print media sources used by sailors to help with their choice of steed are little more than just another cog in the marketing machine.

The differences between the USA and Europe in terms of the types of boat used and favoured for bluewater activities are huge. Why? It is difficult to look any further in pursuit of an answer than the fact that one region relies on word of mouth while the other relies on marketing. It seems logical that the personal experience of sailors would carry more weight than advertisements and test reports of uncertain provenance.

I know from my own experience that products can successfully find a market without so much as a mention in the media given a critical mass of word-of-mouth recommendations.

Books and bluewater seminars can provide further food for thought for sailors with purchasing decisions to make, but only if they tackle the uncomfortable truths head on (which, as I address in my observations on the monetarisation of these seminars, might not always be as straightforward as we would like to think).

The advice now offered may well extend to include the differences and key features of steel and aluminium hulls, but there is – in my opinion – still too little attention paid to the hull appendages and to their suitability for use away from coastal waters. This applies in particular to GRP designs, some of which are produced in (relatively) vast numbers. Flotilla organisers’ safety tests and mandatory equipment lists are sensible enough in themselves (ensuring each boat has an emergency tiller that actually works is certainly a big step in the right direction), but they do nothing to address the risks inherent in the basic design of these boats and the worrying implications for the offshore sailor.

My object here is to highlight the design features that really matter on boats destined for blue water – features that can become critical for survival in some circumstances.

RATIONAL DECISION-MAKING ON THE UP

The evidence in my segment of the market has been building up for some years: tried-and-tested hull forms are making a comeback. Yachts with a long keel are becoming very popular again because they apparently just make sense to a large part of the prudent bluewater public.

My list of the designs commonly fitted with a Windpilot includes:

332 Hallberg-Rassys of all sizes

68 Monsun 31s

72 Contessa 26s, 32s and 35s

48 Vega 27s

17 Tradewind 35s

16 Rival 32s and 35s

20 Rustler 36s

17 Pacific Seacraft

16 OE 32s

22 Albergs of all sizes

17 Allegros of all sizes

15 Breewijd 31s

15 Bristols

32 Breehorns of all sizes

18 Endurance 35s and 37s

63 Nordic Folkboats, IF 26s and Marieholm 28s

14 Island Packet 35s, 37s and 45s

18 Laurin 28s and 32s

34 Nicholson 31s, 32s and 35s

13 Passport 40s, 42s and 45s

85 Colin Archers of all sizes

22 Tayana 37s and 52s

11 Westsail 32s and 42s

This is just a quick extract on the fly from my database, which covers virtually all of the series-produced yacht designs for which I have manufactured and supplied systems over the last 40 years.

Dies ist nur ein schneller flüchtiger Ausschnitt aus meiner Datenbank, die nahezu sämtliche jemals weltweit in Serie gebaute Schiffs Typen umfasst, für die ich im Verlauf von 40 Jahren Systeme produziert und ausgeliefert habe.

GOLDEN GLOBE RACE

it seems perfectly logical to me that traditional designs are back in favour. The entry list for the 2018GOLDEN GLOBE RACE 2018 for example, reads as follows:

Rustler 36 (6)

Biscay 36 (4)

Lello 34 (3)

Belliure Endurance 35 (3)

Suhaili ERIC design replica (2)

Ta Shing Baba 35 (2)

Tradewind 35 (2)

Nicholson 32 Mk 10 (1)

OE 32 (1)

Benello Gaia 36 (1)

News zum Golden Globe Race 2018

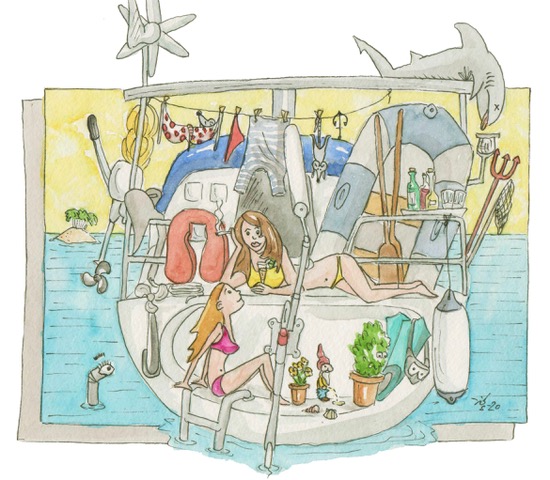

EASY ON THE EYE

This article by a US based owner Skipperswho has become very familiar indeed with the rudder bearings on his HR Monsun 31 in recent years gives a good idea of just how solidly the rudder is attached on a boat like this. I can imagine a few owners of modern performance cruisers with a balanced spade rudder blanching at the very sight of these pictures!

Here endeth the lesson for today…

Peter Foerthmann