WHAT EVER HAPPENED TO BOAT BUILDING ?

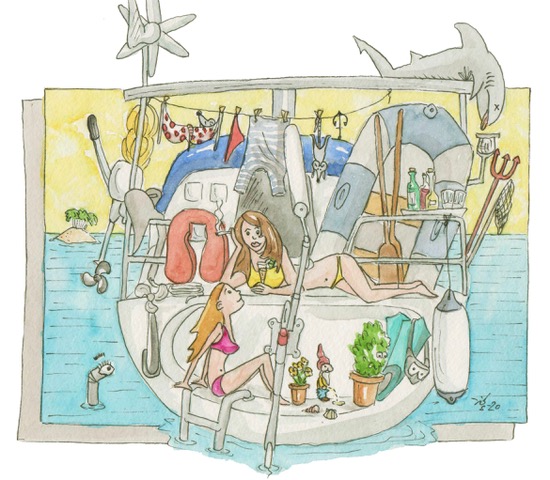

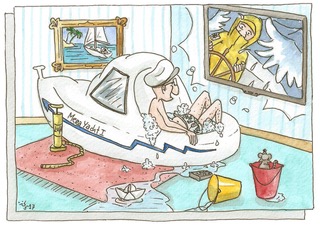

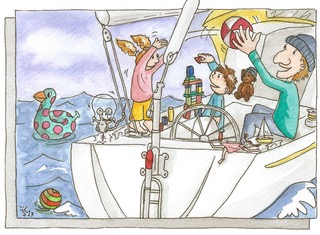

Few topics are as controversial among sailors as the quality of the boats we invest in to help realise our dreams of a life afloat. Obviously, choosing a boat ranks as one of the key decisions for any sailor: a choice that proves to have been a poor one can have serious and far-reaching consequences – and is by no means straightforward (or inexpensive) to rectify. Take on too much of a financial burden, leave yourself too much to learn or trust too much to your own handiwork and you could end up in trouble, especially if the press-ganged family, left at the mercy of your orders from the bridge, also has to live with your misjudgements as immortalised in composite, aluminium or steel. A wise choice right at the beginning can make all the difference in the world to the fun to be had under sail, so it seems astonishing that so many of the issues involved are so seldom properly discussed.

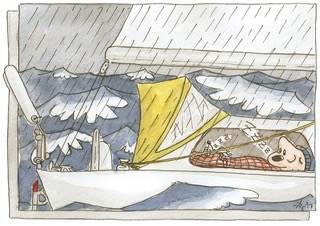

Polarised debates of the traditional = better/modern = worse type might be very effective at filling pages on internet forums (in the process bringing out the intransigence, entrenched positions, rapid loss of perspective and ruthless jump to character assassination that seem to have become the staple fare of this platform), but they fall well short of the level of insight required. The issues involved are more complex: expect rough seas ahead!

It is quite extraordinary that these matters receive so little consideration in the sailing press, although the fact that our press has become, willingly or unwillingly, so dependent on its advertisers might perhaps have something to do with it. Our would-be critics have simply washed their hands of the whole notion of quality, with any criticism limited to fairly trivial points such as headroom, berth length and interior furnishing. The fundamental properties of a product as a seagoing vessel are seldom even considered, let alone subjected to a rigorous comparative investigation.

The transformation of boat building from a craft into an industrial process and, in particular, the implications of this change in terms of the quality and price of the product seem to me to be fundamental issues for our sport and yet they are hardly eating up the column inches. Nothing sets the opinions flying like an open debate on then versus now, but there are a number of distinct aspects to consider if we are to do the subject justice:

– How boat building has changed from a craft into an industrial process

– Materials and their use

– Speed and seakeeping ability

– Intended and actual purpose

– Lifetime and maintenance requirements

– Marketing and its costs

– Value and resale

Clearly sailing could never have become widely accessible as a sport without the introduction of mass production in GRP. The smaller the boat, the bigger the potential market open to it and hence the more units to be sold. Optimists and Lasers have been churned out in their millions, or least hundreds of thousands, and while yachts have never shifted in these numbers, their extra features – everything from heads to an engine – make them much more interesting in terms of the value to be extracted per unit.

When yacht production first began to move onto something approaching an industrial scale, the small number of manufacturers offering boats at shows in Europe could have sold dozens of each model every time they exhibited. The Seventies and Eighties were gold rush time as sailors beat a path to the boatyard gates and demand soared. Brian Meerlow and his team in England built thousands of their Leisure yachts, for example, back when nobody worried about breathing in styrene vapour and extractors were unheard of.

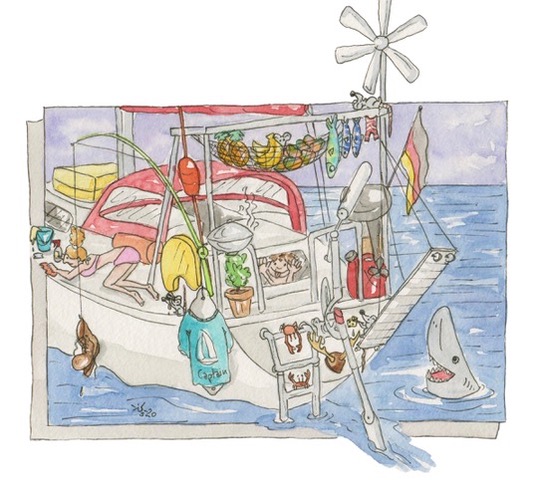

Coincidentally it was to Brian that the founder of my company, John Adam, turned in 1968 in his search for something small and seaworthy to win him some respite from excessive strife on the domestic front. Armed with a Leisure 17, he headed West and eventually found himself on the beach in Cuba having fallen asleep and run aground. It was while cooling his heels in one of Castro’s prisons that he made the decision to set up Windpilot: the first vane gear had after all passed its test with flying colours (keeping watch – then as now – not being a part of its remit).

John’s story created a sensation at the time in Germany so that all the marketing professionals in the world could not have coordinated a better market launch for Leisure yachts. The brand retains a special aura to this day, with over 4000 Leisures sold and almost all of them still in existence. But I digress…

The number of people eager to get afloat was simply too high for traditional production methods and craftsmanship to cope. Consumers were no more patient then than they are now: once they felt the itch, they wanted deck beneath their feet and pronto. When it comes to impatience, children on Christmas Eve have nothing on grown men and women waiting for a new boat to arrive. The transformation in the nature of boat building precipitated by these pressures was dramatic. The process was – almost literally – turned upside down (or inside out, depending on your point of view) and ever since, boats have been built the wrong way around: today everything starts with the skin and not the bones.

Henry Ford started exploring the possibilities of assembly line production a century ago, but it would be another 60 years before boat builders first sat up and took notice.

Originally the hull of a boat was a very complex assembly: to keel and keelson, stem, sternpost, stringers, deck beams and ribs were added planks as thick as a seaman’s thumb and the whole thing was bolted, nailed and glued together, sealed, sealed and sealed again and then finally treated to several coats of paint to create a thoroughly robust and watertight structure. All of which took some time…

A finished hull of this nature came ready to sail; there was no need for extra interior structures or fittings to help spread and absorb the working loads. To keep the weight down, racing yachts often started life with nothing below but pipe berths and were only fully furnished at a later date if and when racing gave way to luxury cruising. Whether to hit the race course with a crack crew or embark family and friends and concentrate on seeing and being seen was a matter for the owner: the yachts were tough enough for both lives – in fact they still are. In those days the cost of the hull made up an eye-watering proportion of the overall price of the boat. Boat builders were craftsmen, not magicians, and bending wood takes time (although of course man hours were not at all expensive in that era).

Rationalizing hull construction was the logical way to go – and it is here that the rot set in! Once a female mould had been engineered, ready-made boat shells could be turned out one after the other like so many bread rolls in a process that suddenly no longer needed the expertise of skilled boat builders.

It is characteristic of the modern classics that although they have a GRP hull, they were still fitted out by craftspeople, that is to say skilled boat builders still had a hand – and earned a crust – in their production. Also no secret is the fact that older GRP boats tend to be considerably more solid, because stringers, bearers and wooden interior components are all laminated into the hull. The resulting structure is very stable, especially since the stringers and bearers are bonded face-on and the interior components edge-on.

Take my Hanseat boats, of which I have had three, for example. They were always perfectly quiet to sail even in a good breeze and the deck never creaked even when the summer hoards stampeded across on their way from the far end of the raft to the bar. In those days sailing boats were still seen and not heard.

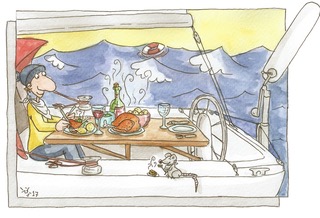

Modern classics enjoy great popularity today because of the way they combine the beautiful lines and traditional craftsmanship of old with modern materials. And, at a more basic level, because of the way they allow families – even those members with a more sensitive nose – to take to the sea without the damp reek of stale air and musty socks that tends to pervade the more traditional of traditional craft.

There is more to boat building than right angles; indeed their very curvaceousness accounts for a big part of the appeal of those striking little ships whose lines alone set hearts pounding and bank accounts quaking. On a more practical level, it also makes sure that no matter how soundly you slept, you quickly remember that you are on the boat and not in the house. Rights angles really were an unusual sight in this era, which for me explains much of its charm and elegance.

The visual language of traditional design was emotional: function followed form and not vice versa. Today the mainstream marches to the beat of a different drummer, with aesthetic concept and product shaped by marketing diktats and design vocabulary serving only to ensure brand recognition and distinctiveness.

The boats of the past were undoubtedly more robust. They had a backbone and ribs, meaning they were better armed against ramming, stranding, grounding and other extreme encounters, and carried their rudder firmly mounted and safely tucked away in the sweet spot at the trailing edge of the keel. Modern yacht design specifies no such backbone. It has been spirited away to be replaced, here and there, with other structural members in much the same way that many car manufacturers have done away with any distinct chassis to leave each individual component apparently supported only by the parts around it.

Interior shells and moulded parts have increasingly driven traditional boat building out of interior construction too on the basis that separate units and components can be mass-produced rapidly and installed inside a bare hull equally quickly. Boats today are built in a modular fashion, which simplifies customizing and cuts costs. Moulded components can also incorporate rounded edges and corners at no extra cost to suggest at least a token element of design flair.

This video clip of a guided tour of a well-known yard illustrates the modern process. The commentary is in German, but the images really speak for themselves.

Today hulls are reinforced in critical areas with bulkheads, interior shells, longitudinal stringers and space frames to make sure that when the boat is lifted out, the keel comes too, that the engine doesn’t slowly make its way up the boat while motoring and that the pressure transmitted from the mast above when sailing close-hauled does not leave hapless crewmembers marooned in the heads. The most extreme designs include additional metal structures to distribute the loads.

Some would have us believe that modern boats are more solid than ever, but can we really believe that? Space has become a more compelling argument and the obvious response has been to do away with the traditional foundation of a strong hull – its frame and ribs – without putting anything obvious in its place. Sailors flock to the resulting space(ous) ships like moths to a candle, for it seems the number of berths has become the measure of all things (and has a not insignificant effect on the price). And who ever stops to consider how this wonder came to pass? Who seriously spends any time thinking about how much – if any – effective load-bearing structure there is behind that smart interior shell?

Perhaps it’s all a matter of perspective. After all, what we don’t know might not hurt us. Although … once I saw a sailing boat at one of the big boat shows that had been sliced in half longitudinally and I couldn’t help noticing just how little substance there would be between the sailor asleep in a bunk of a heeling yacht and the fish swimming past outside. Did that strike a chord with anyone else?

It is no secret that mast, rigging, sails, engine, keel and rudder pull and push the boat in different directions and that hydraulic systems can put a bend in the hull as well as the mast. Only a stiff hull can endure such loads in the long term; once flexing sets in, serious problems are sure to follow. Signs of fatigue on the hull, keel and rudder, soon our constant companions, auger well for the repair and restoration business.

Everyone understands that the half-life of a new stripped-out racing machine is short, that at some none-too-distant point in the future that once proud and resolute bow will begin to acquiesce a little as the sea builds. Life is a compromise – and when it comes to rig tension, it can be a fine line between just right and ever so slightly too much.

We should also note that thanks to cheap materials and labour – and the fact that in those days nobody realised just how thin they could go – laminated hulls on older boats and those built in the Far East are often extremely thick.

Today it’s a different story altogether!

The greatest secret in the increasing industrialization of modern boat building is probably the sharp reduction in production times and concomitant increase in value added. Or, to put it another way, why do international investors and the pin-striped locusts suddenly have yacht manufacturers in their sights?

I know of one sailor who, out of love for his wife and in preparation for the big retirement cruise, decided to swap his dark cavern of a steel yacht for a new – and much brighter – alternative. Keen to be, as it were, in the delivery room to witness the arrival of his new home from home, he cheerfully turned up one Monday morning at the yard appointed to realise his dreams expecting to witness the final stages of fitting out. What he saw instead was a bare hull that, like him, had only just come into the building. He was astonished – and never more so than when the finished boat was handed over right on time just a few days later.

I have seen similar myself in Les Sables d’Olonnes: the project concerned, an imposing new catamaran, was just a week away from delivery and yet there it stood in the middle of the hall, deckless, looking more like a building site than a boat.

Neither I, nor the owner and his wife sitting at home in Bavaria with their sea bags packed and poised, could believe everything would be ready on schedule. But it was – no sweat!

I always seem to end up comparing money invested in yachts with money spent on property (albeit houses too have their weaknesses with the wind on the nose). In Germany, a new family house in a pleasant setting costs in the region of €200,000 and represents thousands of man hours at a moderate level of value added for all of the companies involved. A production GRP yacht costing a similar amount takes a fraction of the time to create – and is then very often compared in price terms to boats whose construction involves a much larger element of craftsmanship.

It is hardly surprising then that terms like “quality yacht” always seem to be applied to more expensive vessels. Obviously, one-offs assembled by craftspeople are going to consume more money in the shed.

It may be interesting – perhaps shocking – to reflect a little on the hours of work that go into producing a finished yacht. The conclusions in terms of the inherent value of any given boat soon become perfectly clear: you do indeed get what you pay for (in more ways than one). It can also be interesting to look at the second-hand market and see how perceptions of quality and value change once long-term use has had a chance to expose weaknesses not apparent on the boat show floor. True quality reveals itself only in long-term use and it is no surprise the sailor’s brain spends a long time quietly accumulating information before eventually coming to a judgment for or against a particular brand.

We are honoured almost every week with the launch of some or other new boat, just about all of them production GRP designs. This speaks of serious rationalization on a scale unknown – perhaps even inconceivable – to ordinary sailors. In fact producers have found ways to rationalize their business in all kinds of areas:

– in design, which is entrusted to powerful computers running sophisticated software,

– in mould making, in which robotic systems capable of five-axis CNC machining do all the work without human involvement (with no lunch break and no desire to go home at night),

– in the construction of the bare hull, which is produced using prepreg materials and vacuum bagging,

– with interior shells, which make it possible to reinforce and partition the hull simultaneously,

– with interior fixtures, which are produced as modules on a separate line and can then be installed into boats as required,

– in the production of the deck, which has the fittings installed prior to being dropped onto the fitted-out hull to seal the finished yacht like the lid on a jar.

That such rapid changes of model are even possible is, without exception, down to the enormous rationalization and acceleration of all processes. Even small production runs can be profitable now. Nevertheless even the biggest yards with global marketing and a lively charter supply business still achieve only modest output when compared with the producers of other high-priced goods, which probably explains the breathless pace of competition: production yachts have to be introduced, promoted and phased out again faster than cars just to keep up the pressure on the other big players in the market. A design lasts just a few hundred units before the focus moves on and the next contender sets sail. In a saturated market, however, there is only limited scope to keep sales volumes rising. We do not (yet) have a scrappage programme for old yachts!

Building a metal yacht remains a time-consuming business and the preserve mainly of one-offs. A high-quality 45-foot custom boat in aluminium might take around 5000 hours to build; a GRP equivalent of the same size would almost certainly be ready to hit the water in a fraction of this time. The GRP version would surely be significantly cheaper too, so it wins hands down – unless, perhaps, other factors like seaworthiness, safety, reliability, suitability for bluewater sailing, performance in use, value-holding ability and ease of resale also come into the equation. But that is a discussion for another time.

If the lively response to the first part of this blog on the German internet forums is anything to go by, this matter may be even more controversial than I suspected: the hornets nest has been stirred, sensitivities have been pricked and unsettled sailors are taking to their keyboards to explain and defend their views and decisions. I would say that one could write heavy books on the subject of these deliberations, but as it happens, most of these books – presenting a variety of perspectives – are already out there.

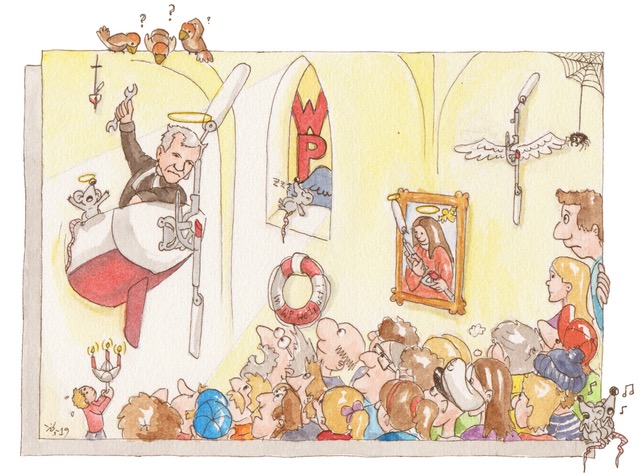

My take on these complex issues is just that: my take. My expertise lies in self-steering and in helping yachtsman and yachtswomen gain a little respite from the tiller or wheel at sea. I do not claim to have eaten the tree of knowledge leaves, bark, beetles and all! The fact that after several decades in the business and dozens of boats of my own, I find my conversations with a global sailing community increasingly focusing on boats as such rather than ‘just’ the choice of windvane, has helped to keep my job stimulating and has led me in the process to develop a particular point of view.

I believe proper consideration of these ideas based on a rigorous investigation of whether modern is always better could trigger – or at least sow the seeds of – a seismic shift in the way some sailors think about boats. Trying to phrase the arguments involved in simple black and white terms serves no purpose in the same way that no one material can always be the right choice for every boat: just as GRP has its osmosis, aluminium its electrolysis and welded steel its rust, so the plank has its worm. While we have to make a decision, we know that compromise is the real name of the game.

Some compromises are better than others, however, and what better way to start an exploration of their relative advantages and disadvantages than with the observations of a certain grey-haired character who, though his age might suggest a rather conservative angle, derives his opinions directly from experience and careful reasoning rather than dogma and stubbornness. Knowledge is a valuable commodity and one it’s hard to have too much of when looking for a new home on the seas.

Although the ideas discussed here relate first and foremost to the yacht intended for longer voyages, it cannot do any harm to reflect on them and how they might apply whatever you have in mind. Sailors are dreamers and their dreams – irrespective of whether they ever come to fruition – almost always revolve around open water and distant islands and it consequently makes sense to consider how the picture may have changed over the years in terms of the quality, robustness and price of the great proliferation of production yachts in which we are now invited to trust. Lucky indeed the sailor who manages to plot a smooth passage through these treacherous waters and find a boat that lives up to expectations even after the trials of long-term use.

Much of the first part of this blog concentrated on the impact of changes in boat building methods, industrialization and value-added considerations in large-scale GRP production on concepts of and approaches to hull construction. Today’s production GRP yachts have become far removed from the traditional understanding of what a hull should be and how it acquires its strength. Traditional structures are not necessarily the only solution, but the sense of security their solidity conveys is certainly a nice feeling.

I believe that boats were built better in the past essentially because the methods then employed produced a more robust vessel. And in those days hull, keel and rudder formed a single strong unit, which is always a plus in my eyes. The hull of the typical modern production GRP yacht (I will look at metal hulls another time) consists of just a shell. Keels are manufactured separately and then bolted on, which is both practical – from the manufacturer’s perspective at least – and reduces costs. The implications of the shell approach for bonds, joins, seaworthiness and endurance are widely understood.

It is no accident that modern underwater shapes always include bolt-on extremities in place of the traditional V-form forefoot, guarantor of a smooth ride through waves, good seakeeping and relative peace and quiet down below. Today speed often seems to be the only element of performance that counts. The gung-ho yachtsman can imagine nothing worse than being passed to lee by a bathtub and inherent strength is the asset many seem willing to sacrifice – at times apparently without even beginning to consider the consequences – on the altar of vanity. Why else would it be that more and more offshore events, even those organised primarily for cruisers, are making it mandatory for participants to carry an emergency rudder in order to spare the rescue helicopter the need to launch every time a steering cable jumps off a block?

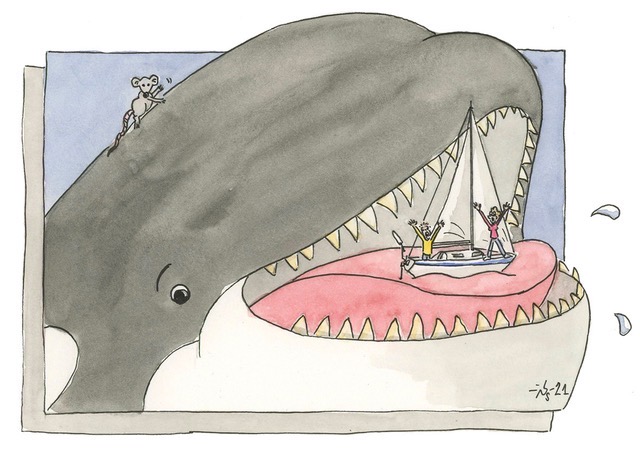

A quick glance at the spacing of the rudder bearings and the leverage that can be exerted on them in most modern designs should provide more than enough material for seafaring nightmares. A spade rudder is certainly efficient in form and effect, but it also makes a tremendous lever and experience suggests the force applied at the bottom at times exceeds the strength of the mounting structure at the top. Not everyone can walk on water and those of us who can’t might do well to avoid knowingly putting ourselves in this situation rather than just trusting the sat phone, EPIRB and shortwave radio to buy us a second bite at the cherry.

One Kiwi professional delivery skipper is said to have “worn out” several balanced rudders in the course of taking a European production yacht home to New Zealand. Stories of problems with keels and rudders fill an increasing proportion of the nautical press – although, since they tend to affect solo sailors with the necessary wit to find their own way home, they seldom make headlines outside of the sphere of sailing.

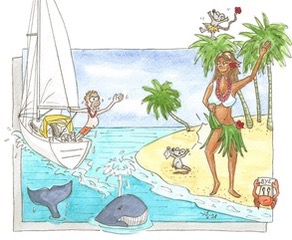

Performance (insofar as it is confused with speed) also has another dark side of which anyone who values the chance to sleep in peace at sea ought to be aware. The number of sailors quickly and quietly trading in their fast rides for better all-around offshore performers is rising rapidly. One seafaring family recently sold their brand new yacht in a hurry at the end of its first bash across the Atlantic, preferring instead to continue their planned trip around the world with a 40-year old classic. While expensive in cash terms, their decision has proven to be the right one and they remain very happy with their replacement to this day

Others have been less fortunate.

Swiss circumnavigator Thomas Jucker puts it very succinctly: “Sailing to New Zealand around the Cape of Good Hope in a lightweight boat is actually not particularly difficult – but it isn’t much fun either.” Jucker currently sails a Bristol Channel cutter.

Just anecdotes? Of course, but there are plenty more where they came from and they tell a consistent story – a story even ordinary sailors who do not spend their whole life at sea would do well to heed if they really want to be able to trust in their boat. The open ocean, of course, has no monopoly on uncomfortable conditions: the combination of strong winds, powerful currents and prominent landforms can put yachts to the test even close to home.

When every week brings new models, glowing test reports and more slick marketing to match and when each successive development seems intended only to make us forget what has gone before, it takes a stoical composure to read between the lines and seek out the real purpose of this spiral of gloss. We can be certain, however, that new does not automatically equal better. Older boats still making their way under sail have proved they can last the distance: novelty in and of itself is no reason suddenly to consign them to the yacht cemetery!

That, at least, is the conclusion so far of

Boatbuilding and the market

Once more into the breach!

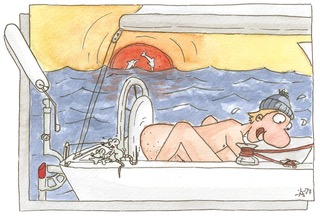

The only way to be sure a boat is really robust and well-built enough for long-term use is to put it to long-term use – or break it trying… However the typical year for most seafarers yet to shed the shackles of the rat race amounts in total to no more than a few weeks under sail in a good year and less than a hundred hours on the engine in a bad year: most boats spend most of their time turning silent, solitary circles around a mooring buoy or staring at an empty car park in the vain hope that today, at long last, the skipper will finally put in an appearance and let them off the leash.

I wouldn’t want to put an exact figure on the number of nautical miles required to reach a verdict, but I do think considering the relative merits of different boats in long-term use is a good way of establishing the criteria that really count in practice. It is self-evident that yachts used for bluewater voyaging have to withstand far greater loads than fair-weather weekenders. Strongly tidal waters and the higher latitudes also have their challenges I concede, but we cannot penetrate to the heart of the matter without considering proper long-term offshore exposure.

A design’s ability to hold its value over time is a key indicator here: any owner whose boat is known to have come up short in the moment of truth can expect to see its resale value evaporate like sea spray on a hot day in the Canaries. Boats become permanently unsalable if the nautical community gets wind of any serious weaknesses.

Obviously the yachts we turn to as the vehicle of our sailing fantasies in generally show far more endurance than their crew. When conditions deteriorate, the great majority of sailors head straight for the nearest port, teeth clenched, without ever giving the storm sails a chance to shine. The more unpleasant memories tend to fade quickly, especially away from the water, and soon enough bad times have been reborn as great stories and it’s time to get back afloat. This, of course, is all part of the charm of our sport, but it does nothing to alter the fact that most boats are only very seldom really put to the test. While this may be good for the manufacturers (nobody likes complaints), it does increase the risk of sailors only discovering the true limitations – and absolute limits – of their vessel once it is too late to find an easy way out.

We could of course turn a blind eye to stories of trouble at sea, keep our thoughts within our comfort zone and specifically avoid learning just what can happen in extreme conditions. This approach, I would suggest, is likely to be more popular among those who have reason to fear their own judgment: it cannot be a nice feeling to buy a boat for one set of reasons and then fall out of love with it on other, far more compelling grounds.

The matter of hull strength we have already done to death and there is nothing to be gained be revisiting it. But what about keel, rudder and engine? A saildrive, for example, which leaves the crew parted from the fishes by just a few millimetres of gasket, can prove the Achilles’ heel of an otherwise robust yacht. Saildrives have insidiously worked their way aboard all kinds of designs now thanks to the fact that they are much quicker for the yards to install, but they remain a matter of concern among insurers and have proven by and large to be a retrograde step in the long run for us sailors.

Here too the new ‘solution’ fails to measure up to the older ideas it has replaced: commercial shaft drive systems always include a thrust block to pass on the thrust from the shaft, but force transmission in a saildrive system is inherently unfavourable because of the way thrust generated in the basement has to be tamed and transferred a whole level higher up in the structure. This is quite different to the situation with a conventional drive, which transmits its propulsive force to the backbone of the vessel in a straight line and, of course, enjoys a protected location tucked in at the trailing edge of the keel. The difference in terms of the work involved in installation and alignment between a conventional shaft system and a saildrive amounts to many hours – too many hours for the major production boatbuilders to ignore. For sailors, however, the case is not so clear cut: while a leaking stern tube is certainly annoying, it is nothing compared to some of the problems encountered with a saildrive.

Class association publications and resources can be an excellent point of reference when trying to assess the long-term qualities of production yachts, as they describe known weaknesses and solutions and can provide useful tips to help owners make the most of their investment (here are some links to well-known owners’ associations, some of which enjoy almost legendary status among the cognoscenti:

Contessa 26; Contessa 32; Westerly; Sadler; Hans Christian; Hurley; Moody; Island Packet; Valiant; Cape Dory; Westsail; Bristol; Cheoy Lee; Passport; Corbin; Hallberg Rassy; Najad; OVNI). Just about every reputable brand operates an Owners’ Association (albeit a few find the temptation to use it mainly as a marketing platform for new models hard to resist).

The Contessa 32 occupies a special niche in the used boat market thanks to its exceptional build quality. Take an example with a lifetime of use (30 to 40 years in many cases) already behind it, send it for a full refit with the original builder and you have a boat as good as new ready for another lifetime of adventures. Yachts like this hold their value and represent a good investment for their owners. The same cannot be said at the moment for many of the more common modern production yachts, whose resale prices are seriously compromised by the sheer volume of options available in the second-hand market. As elsewhere, market activity and prices depend on the balance of supply and demand, with excess demand pushing up prices and enabling sellers of the most coveted models to walk that little bit taller on the way to the bank. If there are more sellers than buyers (say, for example, the market becomes flooded with retired charter yachts), however, boats will only sell, if at all, at a substantial discount.

The Contessa 32 occupies a special niche in the used boat market thanks to its exceptional build quality. Take an example with a lifetime of use (30 to 40 years in many cases) already behind it, send it for a full refit with the original builder and you have a boat as good as new ready for another lifetime of adventures. Yachts like this hold their value and represent a good investment for their owners. The same cannot be said at the moment for many of the more common modern production yachts, whose resale prices are seriously compromised by the sheer volume of options available in the second-hand market. As elsewhere, market activity and prices depend on the balance of supply and demand, with excess demand pushing up prices and enabling sellers of the most coveted models to walk that little bit taller on the way to the bank. If there are more sellers than buyers (say, for example, the market becomes flooded with retired charter yachts), however, boats will only sell, if at all, at a substantial discount.

A few minutes in the company of Google and the usual portals can give a pretty good idea of the market value of used yachts (although it should not be forgotten that there can be a big gap between asking price and actual selling price and selling prices hardly ever become public knowledge). That today’s market is a difficult place even for high-quality yachts from respected yards is evident from the way so many pre-owned examples take such a long time to find a new home. The classifieds pages of leading sailing magazines contain innumerable repeat ads, with boats commonly taking several years to sell despite being advertised with good photos and plenty of detail. Brokers have no magic power to speed up the process either – in fact there is often little they can do other than add yachts to their own listings and advertisements.

And yet craft from certain yards still seem to sell with ease. Second-hand KOOPMANS yachts, for example, regularly command excellent prices – irrespective of hull material – and are commonly snapped up almost as soon as they become available. OVNI, GARCIA, BESTEVAER, VAN DE STADT, HUTTING and other aluminium yachts also often seem to change hands quickly with little fanfare at a price strong enough to spare seller’s blushes. The stand-out performer among the GRP builders meanwhile is BREEHORN, whose Koopmans-designed boats are purchased almost exclusively by private buyers and are in most cases used for long-distance and offshore sailing. Their seakeeping, construction and robustness have elevated Koopmans yachts in the European market to a position similar to that once occupied by Sparkman & Stephens.

A good reputation, which boosts resale value immeasurably, can only be earned through satisfied customers. Word of mouth recommendations are becoming increasingly important for manufacturers today: full-page glossy adverts carry little weight if the people who actually sail the boats featured are left unimpressed.

A good reputation, which boosts resale value immeasurably, can only be earned through satisfied customers. Word of mouth recommendations are becoming increasingly important for manufacturers today: full-page glossy adverts carry little weight if the people who actually sail the boats featured are left unimpressed.

As for the special qualities of aluminium yachts, that is a subject to which I intend to return another time…

Peter Foerthmann

Without wishing to mourn unduly the passing of traditional boat-building skills or to brush aside several decades’ worth of developments in yacht design, I believe we can safely agree on the following:

modern industrial production methods have greatly reduced the amount of effort, as measured in hours of work, involved in building a sailing boat (manufacturers would otherwise have little interest in mass-produced yachts – the scale of the potential value added is what sets the big players salivating).

modern industrial production methods have greatly reduced the amount of effort, as measured in hours of work, involved in building a sailing boat (manufacturers would otherwise have little interest in mass-produced yachts – the scale of the potential value added is what sets the big players salivating).

It seems rather curious then that while the automotive industry, for example, generally makes no secret of the number of hours of work required to manufacture different cars, the amount of time taken to build a boat never gets an airing in public. We have to content ourselves with speculation – and we speculate that it probably does not take very long at all. Also striking is the fact that while modern production yachts progress through the yard very much faster than their predecessors, the price we pay for them has not fallen at the same rapid rate.

Today’s volume manufacturers manage to maintain extensive ranges and unveil new models frequently despite selling but a modest number of each design. We can deduce from this that, thanks to modern moulding techniques, they do not have to shift many units of a new product before moving into profit. How else could they carry on launching new products at the current breathless pace?

With the price of a new boat now broadly comparable with that of a fairly serious piece of real estate, I do not think it unreasonable to raise the question of just how well today’s craft hold their value. While marketing can affect this to an extent, sailors are very well attuned to more concrete factors – notably the quality of their floating beauties as verified in long-term use and, of course, simple supply and demand – and it tends to be these that determine the price for which pre-loved (or not) boats eventually change hands.

Some would apparently like us to believe a yacht has a maximum life expectancy after which the scrap heap beckons, but as sailors our heart, our head and our experience all tell us otherwise. Consider what happens in other areas. When it comes to a house, for example, the principles we apply are quite different. We more or less take it as gospel that in the long term, the price of a home in bricks and mortar moves in one direction only: upwards.

Cars, in contrast, begin losing value and integrity to depreciation and rust from the moment they leave the showroom and only the passing of the years reveals which models have the wherewithal to bounce back as classic collector’s items and which go for scrapping ready to do it all again in some other form.

How the value of our floating assets evolves in practice largely comes down to build quality, but it’s hard to imagine any sailor accepting that his or her boat would be ‘sailed-out’, as it were, after a certain number of years and then being prepared to accept any price on the grounds that anything is better than nothing for an ‘end-of-life’ product.

Sailors have a highly refined sense of value when it comes to their boats. However finding a potential buyer with a similar view of worth is proving especially difficult for many sellers at the moment and while those of stout heart can usually manage a polite refusal, responding to a perceived derisory offer for a boat in which you have invested  so much of yourself can be a painful business (such situations are handled more dispassionately in the USA, where sellers seem able to accept or refuse offers freely without any sense of personal insult – emotions play no role here and tears are seldom shed).

so much of yourself can be a painful business (such situations are handled more dispassionately in the USA, where sellers seem able to accept or refuse offers freely without any sense of personal insult – emotions play no role here and tears are seldom shed).

But back to the matter in hand: the better its quality (which equates more or less to how well it is built), the better a yacht will hold its value. The venerable old-timers already enjoy a strong market and the new classics are following a similar path. Mass-produced GRP yachts, in contrast, are available in huge numbers second hand, in most cases at broadly similar prices, but sales have become increasingly rare and the market has just about ground to a halt. Deep price cuts now represent pretty much the only way to attract a buyer. For months my head has been absorbing scarcely believable facts about boat sales and the prices actually paid for thoroughly respectable yachts. These are good times indeed for sailors on the hunt for the perfect steed: buyers reign supreme. Well, almost. Extraordinarily, the market for aluminium yachts seems to march to the beat of a different drummer entirely.

I am sure sailors of all persuasions understand that aluminium hulls are in a completely different league when it comes to build strength and durability. They are just inherently more robust in all respects than production GRP boats.

Anyone harbouring any lingering doubts should spend a few minutes browsing the photo archive of insurer PANTAENIUS, which gives a fairly compelling insight into the toughness of boats that fall foul of extreme weather, get too friendly with another boat or otherwise overindulge in off-piste activities.

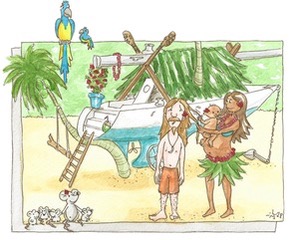

Almost all of the metal yachts built in Germany come from small-scale builders with little or no production automation, so hull costs alone tend towards the eye-watering and the price of a finished boat is seldom less than staggering. One-offs aside, Germany is quite insignificant internationally as a producer of aluminium yachts; in fact the only German company to have achieved significant numbers is Reinke, whose hard chine designs can also be built by fearless DIY-ers (just how many projects there are languishing half-finished at the end of gardens all over Germany after would-be boat-owners found the work harder than anticipated, the costs more than they could stomach or the looming prospect of divorce too unattractive to contemplate nobody knows, but it’s likely to be more than a few). Self-build projects offer little prospect of adding value, as no matter how well they may have performed in use, home-made boats always bear the stigma of amateur construction and the associated fear that perhaps not everything has ended up quite as it should. Building a boat represents a much more complex undertaking than something like building a house and many sailors have found their self-build dreams in tatters sooner or later because they embarked on the adventure without having had the scale of the task made clear to them.

Although Germany has several manufacturers capable of holding their own internationally in the field of production GRP boats, it has seen little if any significant innovation in the production of aluminium hulls. We need look no further than Holland though for a good example of what can be achieved.

The Dutch have quite a number of yards that have transferred the production methods learned in ship-building to yacht construction: computer systems control the entire process, from lofting whole sections to cutting out the various components (using plasma cutters) and shaping and finishing them, which makes it possible to produce a finished hull with minimal tolerances and very smooth lines. The result is yachts with a perfect surface finish that need no more than sand-blasting; filling and painting are seldom required.

The traditional frame designs and spacings used in aluminium hull construction of course make it enormously strong too. Even grounding, encounters with ice and other sleepless-night-inducing impact scenarios need not necessarily be a problem for a well-found aluminium yacht. The fact that hulls built in seawater-resistant 5083 grade aluminium do not even need painting means they are ideally prepared for the knocks and dings of everyday use – and further underlines just how different they are to modern eggshell-thin GRP equivalents, which have little in the way of load-bearing structure and seem decidedly fragile by comparison.

Aluminium even has advantages over steel, as Jimmy Cornell, who has been around the world with both, neatly summarises: on his steel boat, the paintbrush used for touching up after the bumps and scrapes of harbour life seldom had a chance to dry, whereas errant helms careless enough to make contact with his aluminium hull received nothing but a smile and “Have a nice day!” After ten years and something like 80,000 nautical miles of sailing, his OVNI 430 still looked fresh as the dew and eager to set out adventuring again with her new owner.

Anyone who has seen how production OVNI yachts take shape at the yard in Les Sable d’Olonnes will understand very well how they have come to be so popular. They are only moderately more expensive, relatively-speaking, than GRP boats, demand and lead times are enormous and the second-hand market is quite stable, as if there had been no financial crisis at all. France has always produced a large number of aluminium yachts, in part perhaps because Eric Tabarly adopted the material early on for his Pen Duicks, but also because French yachtsmen and -women tend to sail more, harder and in tougher conditions. France, remember, is different. A true nation of seafarers, the French, seadogs and landlubbers alike, revel in the record-breaking exploits of their sailors and turn out in huge numbers to support and honour the country’s nautical heroes with a passion reserved in most other countries only for football.

Chatam, Chassiron, Dalu, Damien, Garcia, Levrier de Mer, Madeira, Maracuja, Meta, Romanee, Trireme, Trismus, Trisbal, Reve Tropique, Via: largely unheard of in the wider world, all of these highly robust yachts – some available in steel only, many in steel or aluminium and some in just aluminium – have an extensive history of bluewater voyaging, are lively and long-lived and find themselves much in demand.

German circumnavigators Astrid and Wilhelm Greiff, long-standing friends of Jimmy Cornell and representatives of World Cruising, completed their lap around the world some 20 years ago in a French Via 42, a boat whose builder subsequently ran into financial difficulties when its great attention to detail turned out to be unprofitable. Via centreboarders, with their skeg- and heel-mounted rudder, are today a highly sought-after rarity.

One of the peculiar features of the aluminium boat-building scene is that aluminium boats very seldom make an appearance at boat shows. Why should they? It’s not as if the yards are short of orders… While this alone speaks volumes, it is also probably worth mentioning again that the cost of attending boat shows, like other marketing and sales costs, passes straight into the purchase price. Hence a manufacturer that can market its yachts effectively without having to stump up for boat shows can put more of its revenue into delivering a high-quality product. Painful it may be to admit, but logically it makes perfect sense.

NORDSEE yachts, all of them built by Dübbel & Jesse on the island of Norderney on the German North Sea coast, enjoy legendary status in Germany and are highly prized in the second-hand market. Few ever come up for sale, however: once acquired, they tend to become family heirlooms, with successive generations of sailors appreciating their outstanding quality and building a firm conviction that after this, any other boat would be a backwards step. Unfortunately the production of Nordsee yachts ended with the tragic death of one of the yard’s proprietors, Herr Dübbel, and today BENJAMINS in Emden, close to the Dutch border, is probably one of the few German yards still building aluminium yachts professionally in any significant numbers. Skorpion yachts from the FELTZ YACHT in Hamburg also have a solid reputation in the bluewater community. Feltz still works in both aluminium and steel, although most of its business in recent years has come from public authorities and the commercial shipping sector.

The way that aluminium and steel boat-building has fallen out of favour in Germany cannot be explained by any lack of demand, but it certainly does take entrepreneurial vision to guide the development of a yard in such a way as to permit the production of attractive yachts from good designers using the latest construction methods at a price customers will be willing to pay. The Dutch have a thriving and technologically advanced boat-building industry capable of fabricating eye-catching vessels at a reasonable price, so it is no wonder we immediately look to our tulip-raising neighbours whenever the conversation turns to metal yachts. Visit Kooi in Makkum or Koopmans in Sneek and see just how professionally they go about their work and I think you will immediately appreciate why those who sail them have no hesitation in giving these wonderfully robust yachts their full trust right from day one.

Peter Foerthmann

I enjoyed reading your blog on yacht building. I would love to build one of my own someday.

Quo vadis Bootsbau ist mir von dedr Seele geschrieben.

Ich lebe in Brasilien wo die Situation ähnlich ist. Der Brasilianer denkt sofort an Motorboote, wenn von Wassersport die Rede ist. Daher ist es noch schwieriger neue Anhänger für die Segelei zu bekommen. Wenn er aber sich für ein Fahrtensegelboot entschieden hat, ist die Wahl sehr beschränkt. Natürlich gibt es auf dem Gebrauchtbootmarkt genug ältere, seetüchtige und grundsolide Boote, meist amerikanischer Art, aber wer heute ein neues Boot möchte, kann hierzulande nur “pseudomoderne” Cruiser-Racer finden.

Diese Boote, hier gebaut, aber direkt vom idiotischen europäischen Trend abgeguckt, sind ein schöner Mist, was Verarbeitung und Design angeht. Design, ein Wort welches ich hasse. Die Massenpresse will heute uns allen wahrmachen, dass alles was ein Designer geschaffen hat, etwas besonders wertvolles(teures) ist. Dabei sind 99% der Designergegenstände unpraktisch, und kaum zu verwenden. Hier und auf aller Welt. Haben Sie auf einem Designerstuhl gesessen, müssen Sie im ein paar Minuten wieder aufstehen, so unbequem sind sie.

Zurück zu den Booten. Diese heutigen Fahrtenboote haben alle, ein viel zu breites Heck, dass zwei Ruder braucht, weil der Rudergänger mit einem Mittschiffsruder vorn nichts sieht. Also höhere Kosten. Boote mit meht als 8m haben alle eine Radsteuerung, so ein Wahnsinn!

Die Cockpits sind viel zu gross, man kann sich kaum festhalten, alles ist spiegelglatt, Einen Spiegel gibt es auch nicht mehr, wenn etwas in Richtung Heck rutscht, incl. Personen, fällt ins Wasser. Selbstwendefocks sind unbekannt.

Das Unterwasseeschiff ist vom Bug bis zum Hech flach und gerade, und geben deshalb den Booten miserable Seeigenschaften bei etwas Seegang. Bei 30 cm Wellen kracht es da vorn. Habe ich selbst erlebt. Gerader Steven, was soll das!

Aber es sind Kopien von Bavaria und Beneteau, deshalb sind sie gut. Sagen die Segelzeitschriften hierzulande. Alles was importiert ist,ist besser als Brasilianische Ware. Typischen Denken für Leute aus der Dritten Welt

Mein Boot ist ein umgebauter Kielzugvogel, aus Holz 38 Jahre alt, aber er fährt allen 20 bis 23 Fuss langen Booten davon, alten und nagelneuen. Möchte gerne wissen wo in den letzten Jahren der Fortschritt im Fahrtenbootsbau geblieben ist.

Und teuer sind sie, diese neuen Boote!

Mir tun die Käufer dieser Boote einfach leid, aber sie wollen es nicht besser.

Guten Morgen nach Brasilien,

der Tag des Erwachens kommt, wenn der Markt aus den Fugen gerät, bzw. das Angebot riesig und die Nachfrage am Boden. Dann werden die Käufer genauer hinschauen und vergleichen – und erschrocken feststellen, dass die Ware nicht immer hält, was der Preis zu versprechen vorgibt. Die Industrialisierung im Bootsbau hat ganz andere Folgen als sie z.B. im Automobilbau hatte, schlicht, weil hier nur ein klitzekleiner Markt bedient wird ohne den Druck einer internationalen Konkurrenz oder einer kritischen Presse, die z.B. durch Crashtests Mängel offenkundig macht und Produkte untersucht und darüber berichtet.

Bei Oldtimer Yachten ist die Entwicklung schon lange deutlich: bootsbauliche Präziosen z.B. von A&R werden heute hoch gehandelt und auch New Classics geraten zunehmend in den Sog von Interessenten, die bemerkt haben, welche Qualitäten diese besitzen.

beste Grüsse aus dem kalten Deutschland sendet

Peter Foerthmann

Hi Peter,

I am passionate about boat building. Your yacht building information is interesting, love the pictures…

good read,keep it up.

i have a dream,since 30 years,around the world,or at least around the atlantic,

retirement just around the corner,so need a project,

so enjoyed your coments.

cheers

andrew

This story reminded me of how I began in the great hobby of building boats.

As a child, my dad would take me to the harbor and I would watch the boats bring in their catch for the day. It all seemed very magical to a young boy.

I started building tiny model boats but due to our familie’s financial situation, I could never graduate to building a “real” boat.

Fortunately, when I grew up and started working, I was able to afford to build bigger boats. However, the plans that I found were incredibly difficult to understand and I never got past the “half-finished” stage.

I was on the verge of giving it all up. Luckily for me, I came across some easy-to-follow instructions that have allowed me to complete some wonderful boats.

I could go on and on, but you would do well to check out the plans for yourself:

http://www.bestquicktips.com/boatplans

Hope it helps anyone reading this!